Week 12: Project's End ... and New Beginning!

- Mao Polosky

- May 20, 2024

- 4 min read

Never Set in Stone: What the Future Holds for Coconut Shell Ash and for my Project

Hello friend(s)! It's been great getting to know each other through the BISV senior project website. Technology is truly a marvel, not just for communication, but also for analyzing and collaborating on concrete, which you'll see soon. Here, we'll conclude the project and reflect on all the challenges we met along the way. Let's get into it!

Link to video of my final presentation: https://youtu.be/OPm337l4T2k

Last Minute Research: Acid-Treated CSA Concrete

On the Tuesday of the week of the presentation, I once again journeyed to Safeway (not sponsored) to buy distilled water to pour into my makeshift hydration chamber at school. This chamber, also used for the previous cubes, consisted of water poured into a Dr. Davies plastic box, in which I placed the cube trays, making sure the water level was over the concrete for continuous hydration reactions to gain concrete strength. Then, I placed another Dr. Davies box on top to prevent hydration. Diagram below.

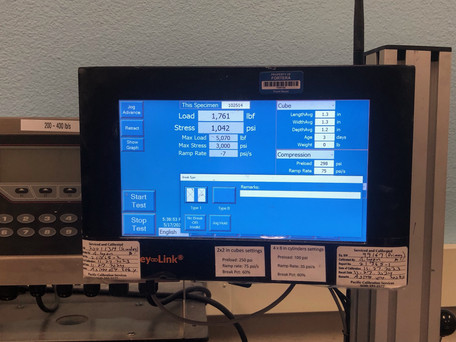

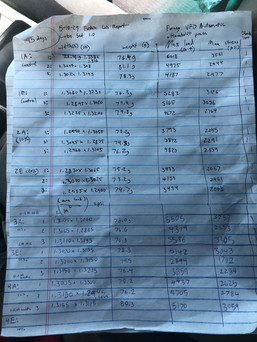

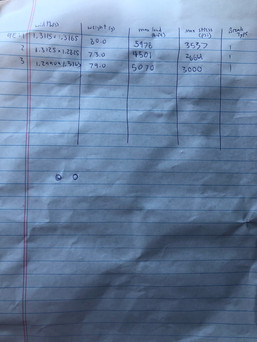

Then, on Friday (the day before the presentations), I brought the samples down to Fortera, and Nick helped me do compressive strength testing once again.

The results seemed promising, with 3/4 of the 10% cement replacement with acid-treated CSA recipes being stronger than the normal 10%. Even so, no conclusion can be drawn, as statistical deviations between cubes within each mix type were too large, up to a 20-30% variation between individual cubes and the average of the 3 same-recipe cubes in some cases. The reason is likely the less controlled hand-mixing method I used instead of the regular concrete mixer. The 4 graphs below, used in the final presentation, demonstrate this point better:

Since some acid remained in the CSA after acid treatment (leading to yield >100%), I accounted for that dilution of the CSA in the 3rd and 4th graphs. There is a trend with decreasing strength as replacement increases, which is not good in the eyes of the industry and the people living in 15-story concrete buildings.

Chemical Analysis Results Bring Clarity, and More Questions

Now, the results of the Industry tests at Cemex also showed similar results in terms of strength loss, so obviously something is up with the Coconut Shell Ash. Electron Microscope Imaging below reveals that despite heavy burning in the kiln for 5-9 hours at 500-900C, the carbon in the ash was only reduced by <10%. Still, this should've meant a bit more strength than the previous project part's unburned 90-95% carbon CSA concrete, so it's odd that it would be weaker now.

Reflections

This project has truly been a culmination. I'm very happy with the interdisciplinary path I set out on, integrating the geopolitical, economic, scientific and environmental factors of concrete, while also exploring a new area within this longstanding industry. I was able to take my knowledge from my favorite classes such as Colonial and Post-Colonial History and Rhetoric (for analyzing papers and world politics and making my speech), AP Environmental Science (for obvious reasons), all the chemistries and STEM classes (for creating experiments and analyzing data), and even Business/DECA/Economics. Not only that, I was able to use my soft skills to learn and navigate the numerous challenges that waited around every hard, concrete corner of the project. Using what we know to pursue new ideas with an endless passion and curiosity, I believe this is the meaning of higher academics and life in general.

As I venture off to college, this experience won't just be a footnote, but a foothold to higher places, whether that be academic success or success in internships/job opportunities. I'm grateful for the experience, and grateful to my amazing friends and family who helped along the way. We do stand on the shoulders of giants after all. I hope to continue working with concrete and other areas that have the potential for massive environmental improvements, continuing to combine society and science in a search for implementable and feasible solutions to save a dying planet.

Future of Coconut Shell Ash and Concrete

Although current results look grim, the humanities-sided literary analysis actually looks at CSA favorably. The main coconut producers (Indonesia, India, the Philippines) are all important members of the Non-Aligned Movement, and could use CSA to meet climate goals set by the UN and the likes, while not getting involved in the global trade wars that characterize the US-China relations by importing more cement or other SCMs. CSA could also be invaluable extra income for impoverished coconut farmers.

On the science side, we need more bulk testing of CSA and novel SCMs to meet the growing demand, while also creating new standards for measuring emissions of these SCMs. On top of that, investigating other materials such as 100% SCM 0% cement geopolymer concrete and recycled materials could lower the demand for cement as well.

As I said before, solutions exist, but making them viable to be applied large-scale is a while other mountain to climb. I don't think this should discourage us though. In fact, humans have always been motivated by a good challenge, and this time is no different. Go out there and start making a difference people, no matter how small. Movement is movement and that is more than most people dare to do.

Keep being great.

Max Polosky out.

Coconut Fact number I forgot: The coconuts of success await us at the top of the palm of challenge. Time to get climbing!

Comments